Harnessing the inherent speed in a high tech carbon lightweight trimaran design while still having a great and surprisingly spacious cruising boat is the secret of Rapido Trimarans’ success, reports KEVIN GREEN for Multihulls World Australia in its September / October 2021 issue. (Photo of Rapido 60, Romanza, Deb Williams, SSANZ)

- Click to download the original article in pdf format, Harnessing the Wind, Kevin Green, Australian Multihulls World magazine, September / October 2021

Below, the article has been reproduced with permission from the author.

Years ago at the start of his new project of building larger cruising trimarans, I met and talked with Rapido co-owner, Paul Koch. It was an interesting conversation, without hyperbole and very factual. It was a very no-nonsense Australian style approach, in fact.

“The whole Rapido trimaran concept came about because we felt the world needed a larger, more roomy, cruising trimaran with good living space that delivered great performance,” he said.

Since then, Koch and his business partner, Richard Eyre have launched the Rapido 60, 50 and very soon the keenly awaited Rapido 40.

During the years I watched the steady development of what is one of the few cruiser-racer trimaran designs and even recall racing against Rapido 60 Hull #01 at the King’s Cup in Thailand, in 2016.

For keen sailors who want performance, the R60 overtook the TP52 fleet on a hard beat clocking 16 knots speed. The four crew were relaxing on the nets while the 16-person crew on the TP52 were on the rail! In another race, an IRC 1 monohull tried to luff the R60 up and failed. So the pointing abilities of the R60 is right up there with racing monohulls.

MORRELLI & MELVIN

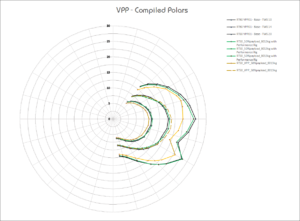

Mention design and the illustrious name of Morelli and Melvin comes to mind. They have applied the latest technology in designing all three Rapido models including their clever use of Computational Fluid Dynamics, Finite Element Analysis and Velocity Prediction Program (see Morrelli & Melvin’s website for more details).

“The innovation in design comes with the layout of the main hull and reaching the balance between beam, draught and trim to carry the accommodation without too much compromise on performance,” said Pete Melvin.

Rapido overcomes the main issue faced by trimarans – berthing – by using folding amas on the 40 and 50. Separately, the Rapido 60 has a unique, highly innovative, design that enables the beams to be unplugged for shipping.

The folding concept was already proven in Koch’s previous trimaran builds which utilized the Farrier-designed folding system. He was the owner of Corsair Marine where he was directly involved in the production of over 1,500 trimarans at Corsair from 1994-2010.

An enhanced carbon version of the folding amas has been developed for Rapido. In addition, this patented folding mechanism keeps the amas in the upright position ensuring that the sides remain free of any unwanted algae growth and barnacles.

Fast forward to 2021 and Rapido’s high tech manufacturing arm, Triac Composites, not only builds all three models, it also did all tooling in its modern factory in Vietnam. The factory boasts a list of equipment which includes a seven axis Kuka milling robot, autoclave, CNC machine, high speed digital carbon cloth cutting machine and a dedicated spray booth. It can also do vacuum infusion and resin transfer molding.

The first R50 has just launched in Spain as I write this. The R40 will be launched in two months and the proven R60 has just been ordered by YouTube sensations, Sailing La Vagabonde, a young Aussie couple upgrading from a catamaran.

CRUISE FASTER

There are some good reasons to consider a trimaran, especially for those looking to combine the best sailing features of a monohull with the stability of a catamaran. While maintaining complete control, trimarans can also offer exhilarating performance.

Trimarans are the fastest, safest, offshore boats as can be seen with the massive French 105ft Ultimes that has kept the Jules Verne (round-the-world) Trophy in its possession due to record breaking speeds. My assignments have taken me on some of these beauties, including one of the newest, the Ultime Sodebo, several ORMA 60s and a crazily powerful MOD70 that I enjoyed for a race at Hamilton Island Race Week.

For mere mortals like me, it’s more the humbler boats that I have really enjoyed sailing, such as the versatile Dragonflys, spacious Neels, nimble Corsairs and classic Farriers. Now Rapido ups the competition considerably with these high tech carbon beauties.

Despite their vast differences, what they all share is a performance efficiency which rewards the discerning and, I hasten to add, the experienced sailor. For example, I’ve buried the ama of small Corsair, which was fairly alarming, but can’t imagine the mayhem if I did this on a 60 foot Rapido offshore at high speed (polars show it doing at least half the true wind speed in lower ranges and a figure of 25kts at 20kts of true wind)! However, thanks to the meticulous design of Morrelli & Melvin, the boat is actually very forgiving according to owners. The massive buoyancy of the amas and righting moment of the Rapido models has been built into the design and is an example of Morrelli and Melvin’s application of the latest technology which sets Rapido apart as a very safe, stable, boat.

Safety, in fact, is a driving factor in Rapido and the carbon foam sandwich construction combined with many watertight bulkheads in the amas and main hull (even the engine compartment is enclosed with watertight bulkheads fore and aft) is such that the boats are virtually impossible to sink.

The Rapido offers performance with incredible stability and is a safe way to cross oceans and for fast passage making. The inherent stability of a trimaran with its nearly square design and weight centred in the middle creates a monohull-style sailing experience with multihull stability.

LIVEABILITY

One downside of trimarans in people’s minds is living space and carrying capacity. In fact, often the first sensation experienced by people boarding the R60 and the R50 for the first time is the great feeling of space! There is an aft deck with side seating and an extra wide helm seat for more than one. Then there are the expansive nets between the centre hull and a huge foredeck.

The cockpit and saloon/ dining/ galley are all on one level. The door to the saloon can swing up into the roof when not in use so that the whole area opens into one enormous space.

The daggerboard dominates the saloon on the 50 and the 60 but the new 40 has ‘C’ foils in the amas and this removes the need completely for a daggerboard case in the saloon which further opens up the interior space. The elevated helm station gives good vision and all sail controls lead to here. This elevated floor plan creates the volume required in the bilges for the engine and tankage which centres and lowers weight – just like a monohull (and unlike a catamaran).

The aft of the salon can be open or closed depending on the prevailing weather or sea conditions.

Inside, the forward master cabin is a double with generous storage, thanks to it being deeper in the hull than the saloon. The cabin includes a head with separate shower compartment. An escape hatch is here, along with one on the stern. Alternatively, two single bunks can be added to the forward cabin.

The aft cabin, has a large double bed with its own head/bathroom. The saloon has an L-shaped settee and table opposite the longitudinal galley which is well equipped with hob, oven and deep sink.

The new 50 has better vision all-round thanks to forward facing windows which can be frosted instantly, literally, with the flick of a switch. It also has a navigation station alongside the settee. Headroom inside both the 60 and 50 is 2m plus. Furnishings, doors and other fixtures are foam cored with veneers for lightness and are fully integrated into the hull for rigidity. The entire fit-out has rounded surfaces to avoid bruising and easily wipe-clean surfaces.

POWERFUL YET CONTROLLABLE RIG

The carbon masts on each model are rotating to maximise performance. The standing rigging is synthetic. An extensive sail plan means there’s a manageable amount of power available both upwind and downwind; an important consideration for safety reasons in a fast boat like this. The furling Solent genoa, mounted on the inner forestay, is self-tacking and the mainsail reefing system uses Karver reef hooks mounted on Dyneema straps around the boom to distribute the loads with minimal chafe.

The boom has truss wings with netting to catch the full-battened mainsail which is on Antal sliders for easy hoisting, reefing and furling. A furling fractional Code 0 and a masthead furling gennaker tack on the bow just ahead of the headstay. Two Harken winches on the cabin top forward of the helm station handle main and Solent sheet loads. Rope clutches for halyards, mast rotation and board up and down controls are positioned to use the same winches.

This efficient use of systems, goes right through the design, says Pete Melvin:

“Compared with cruising cats, cruising trimarans in general are much simpler for their reliance on only one system for steering and propulsion.”

For example, the full-access engine room on the Rapido 60 is next to the daggerboard case at the weight-centre of the boat. All parts of the Yanmar 4-cylinder 53 HP diesel are accessible from all sides. This space also includes the fuel tank, an optional 8 kW generator and space for water makers and other options.

STIFF HULL

Rapido use infused carbon / vinylester laminates on closed-cell PVC cores for high-strength areas and E-glass with carbon elsewhere. Vinylester is used in the hull and deck laminates for good adhesion and better compatibility with the gelcoat finish than with epoxy laminates, which are used in the structural elements of the boat. The build conforms to ISO / CE standards and CE Category A certification.

“We use pre-preg carbon for the high-strength parts such as the cross beams (which are cured in the autoclave), chainplates and bulkheads,” says Koch.

Key hull features included watertight bulkheads and the extensive use of carbon fibre.

Triac Composites’ experienced engineering team and its use of sophisticated technology ensures stringent interpretation of Morrelli and Melvin’s drawings, aided by the trust of Koch’s 30 year association with the designers.

###BREAKOUT BOX 1

Rapido 60 for Sailing La Vagabonde YouTubers

Young Aussie couple, Riley Whitelum and Elayna Carausu went from backpackers to superstar sailors via their video posts on YouTube that gleaned them enough subscribers (a staggering 1.6 million) that enables them to sail full time. Recently, their fame was extended when they took teenage environmental activist Greta Thunberg across the Atlantic in order to reduce her carbon travel emissions.

The couple began their sailing life on a small monohull and then an Outremer catamaran before ordering the Rapido 60.

“We started looking to upgrade and while I wanted a boat that could go fast, I’m much more interested in average crossing times. I mean, it’s good fun to go fast but that’s the least important on my list of things. I want to be able to go at a good pace safely,” said Riley.

After an extensive 18 month global search, well documented on their YouTube channel, the family flew to New Zealand in 2019 for a sea trial with Paul Koch on the Rapido 60 Romanza, owned by Dougall and Jaz Love. The couple were duly impressed, as Riley recalls:

“I know that the Rapido sails unbelievably well, which is the main thrust behind all of our decision making… The only thing I was worried about was the amount of space on board.”

However, after visiting Romanza the couple were more than happy. “When you’re standing in the saloon, you’re actually standing in a huge room.”

Partner Elayna has just had their second child, so had her own priorities for the new boat:

“One thing that was really important for us with the trimaran was that Riley will have the ability to sail it single-handed because we will have two kids on the boat.”

The new boat will be named La Vagabonde III and launch in 2022.

### BREAKOUT BOX 2

Rapido 50 Specifications

- LOA: 15.24m / 50ft 9in

- LWL: 14.96m / 49ft 1in

- Beam: 10.38m / 34ft 1in

- Folded beam: 5.5m / 18ft 1in

- Draft: 0.67-3.52m / 2ft 2in to 11ft 7in

- Displacement (light): 8,200kg

- Engine: Yanmar 38.5hp shaft drive

Sail area:

- SA Main: 95m2 (1,023sqf)

- SA Solent: 54m2 (581sqf)

- SA Staysail: 18m2 (194sqf)

- SA Reacher: 125m2 (1,345sqf)

- SA Asym Spin: 160m2 (1,722sqf)

Design: Morrelli and Melvin

Builder: Triac Composites, Vietnam

Related items